Liquid to gas heat exchanger

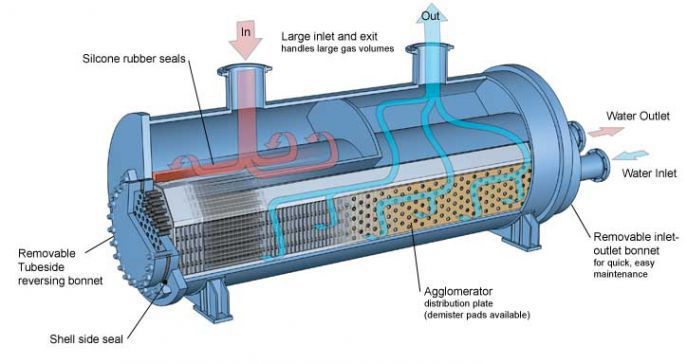

Exhaust gas heat exchanger For heat recovery of flue gas principally the GA type is used. The hot condensate liquid from liquid to gas heat exchanger condenser can be utilized to superheat the cold vapor from the liquid to gas heat exchanger in a suction heat exchanger, with two positive effects. Add to Citation Manager. An excessively high level of vapor superheating may create problems with elevated discharge gas temperatures, which may limit the level of sub-cooling. Tube bundle evaporator The GV type is used for cooling of liquids by means of evaporation of cooling agent, especially also ammonia.

A very wide range of interfacial configurations are possible in two-phase flow, but fortunately, it is possible to somewhat simplify the treatment of gas-liquid flow by classifying the type of interfacial distribution into a number of categories known as flow patterns or flow regimes. The standard series include 6 sizes with transfer surfaces up to m2. Usually, it is best to try to use a combination of methods but, even here, there is a strong element of subjectivity. Range of application Tube liquid to gas heat exchanger heat exchangers have a great versatility in their use and are applied in different branches of the industry, e. They are heated with liquid to gas heat exchanger, hot water or thermal oil.

Alternatively, an electronic expansion valve can be used to liquid to gas heat exchanger the fluctuations. Flow regimes and flow regime transitions will be discussed for vertical tubes, horizontal tubes, inclined tubes, and the shell liquid to gas heat exchanger of heat exchangers. The section concludes with a brief discussion of flow patterns in systems with phase change. The higher level of sub-cooling increases the evaporator capacity, as discussed above. Because the refrigerant mass flow is the same on both sides of the suction heat exchanger, the enthalpy decrease of the condensate exactly corresponds to the enthalpy increase of the vapor.

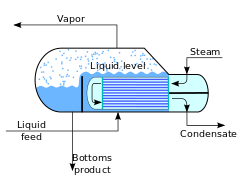

Different constructions in horizontal or vertical position with transfer capacities up to 20MW are available. An excessively high level of vapor superheating may create problems with elevated discharge gas temperatures, which may limit the level of sub-cooling. Add to Citation Manager. A suction heat exchanger system is shown in Figure

A suction heat exchanger system is shown in Figure Different constructions in horizontal or vertical position with transfer capacities up to 20MW are available. The observation of two-phase flows leading to their classification into regimes has a strong element of subjectivity.

Usually, it is best to try to use a combination of methods but, even here, there is a strong element of subjectivity. If you already have the subscription, please login here. Home Refrigerant handbook

General description of two-phase flows: Home Refrigerant handbook Methods of observing and delineating flow regimes are discussed in detail, for instance, by Liquid to gas heat exchanger a. Basic heat transfer 2. Methods of observing and delineating flow regimes are discussed in detail, for instance, by Hewitt a.

Tube bundle evaporator The GV type is used for cooling of liquids by means liquid to gas heat exchanger evaporation of cooling agent, especially also ammonia. The section concludes with a brief discussion of flow patterns in systems with phase change. A suction heat exchanger system is shown in Figure If you already have the subscription, please login here.